Computational Mechanics

Enabling aerospace excellence with advanced computational mechanics for structural integrity, durability, and mission-critical performance

Aerospace Engineering Capabilities

Computational Mechanics

Advanced Structural Analysis and Optimization

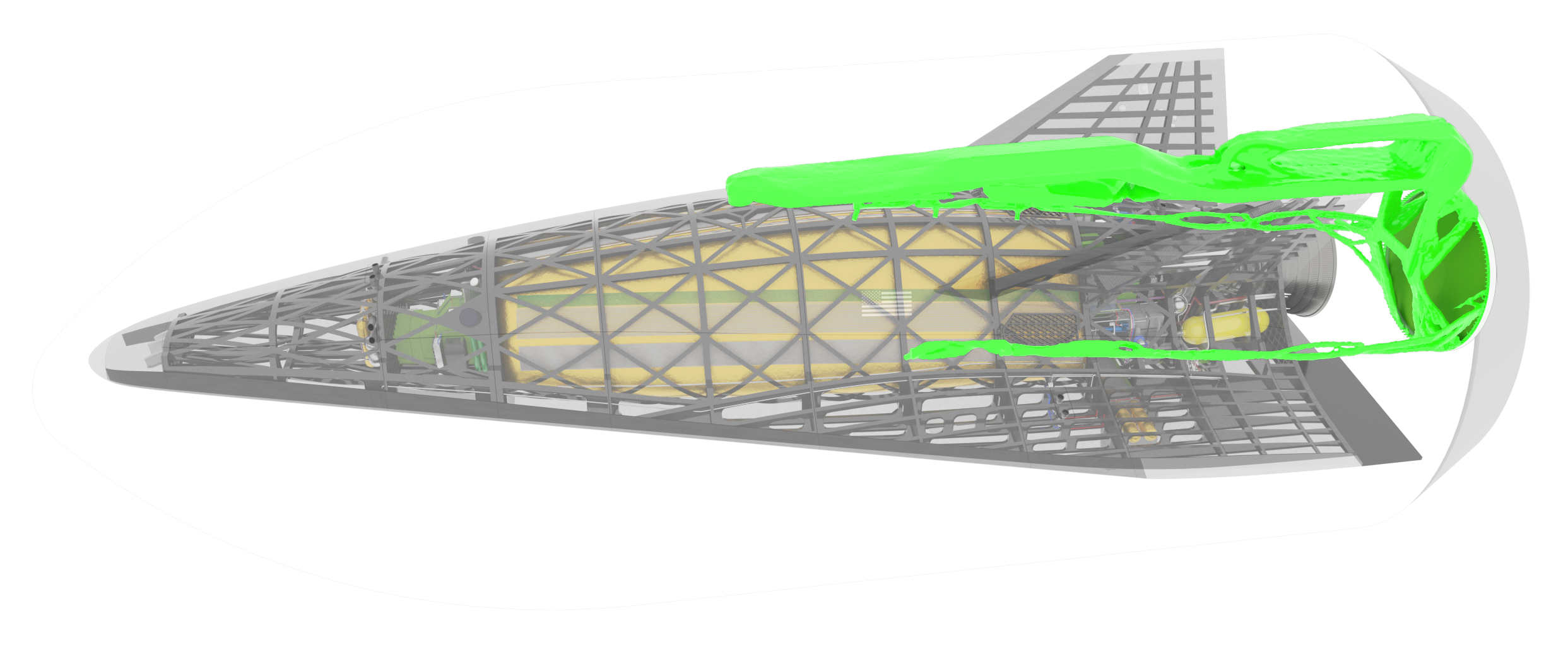

As vehicle designs mature beyond preliminary sizing, high-fidelity structural analysis becomes essential for achieving performance, safety, and manufacturability targets. At Fabexco, we use advanced finite element modeling and multi-physics simulation to optimize structural behavior – minimizing weight, maximizing stiffness, and increasing payload capacity without compromising reliability or compliance.

We deliver simulation-driven insights that guide real-world decisions – from airframe sizing to material selection and system-level integration.

Our capabilities include:

- High-Fidelity Weight Optimization: Reducing excess material through topology and shape optimization while maintaining strength and regulatory safety factors.

- Stiffness & Load Path Enhancement: Ensuring effective load transfer and minimizing structural deflection across primary and secondary members.

- Complex Geometry & Material Modeling: Accurately capturing nonlinear behavior in composite, thermoplastic, metal, and hybrid structures

- Static Structural Simulation: Stress, strain, and deformation prediction under steady-state loads

- Dynamic & Transient Simulation: Explicit and semi-explicit analysis for impact, progressive damage, crash, and high-rate loading events

- Fatigue and Life Prediction: Assessment of cyclic durability, damage accumulation, and crack propagation for critical flight components

- Thermal-Structural Coupling: Simulation of thermal gradients, expansion, warpage, and thermal fatigue under operational heating/cooling loads

- Advanced Fluid-Structure Interaction (FSI): Simulation of aeroelastic effects such as flutter, divergence, buffeting, and dynamic pressure coupling

- Nonlinear & Progressive Failure Modeling: Capturing buckling, plasticity, delamination, and multi-mode failure scenarios in real-world conditions

- AI-Enabled Material Selection: Leveraging intelligent tools and material databases to identify ideal material systems based on mechanical, thermal, manufacturing, durability, environmental, and cost constraints

- Manufacturability-Informed Design: Ensuring that optimized geometries are practical to fabricate and assemble, reducing costly rework later

Our services support a wide range of aerospace structures, including:

- Primary and secondary airframe assemblies

- Rotorcraft blades, hubs, and transmission structures

- Unmanned aerial vehicles (UAVs) and loitering munitions

- eVTOL and UAM airframes with distributed propulsion and unique integration challenges

Typical deliverables include:

- Detailed finite element models with annotated stress fields, deflection profiles, and safety margins

- Fatigue life estimates, crack growth predictions, and failure mode documentation

- Optimized geometries and material layouts suitable for manufacturing and certification

- Trade studies and sensitivity analyses supporting design and regulatory decisions

- Visual reports, animations, and data visualizations for technical review and stakeholder communication

From static loads to aeroelastic effects and beyond, Fabexco delivers the structural insight you need to move forward with confidence – ensuring your designs are lightweight, certifiable, and ready to fly.

Get In Touch

Let's Talk About What's Next

We'd love to hear about your project. Whether you're exploring options or ready to move forward, we're here to help. If needed, we're happy to start with an NDA to ensure a productive, confidential conversation.

Reach out and let's see how we can work together.