Computational Fluid Dynamics

Enhance product performance and efficiency with state of the art computational fluid dynamics analysis tailored to your application

Industrial Capabilities

Computational Fluid Dynamics

Advanced Computational Fluid Dynamics (CFD) Analysis

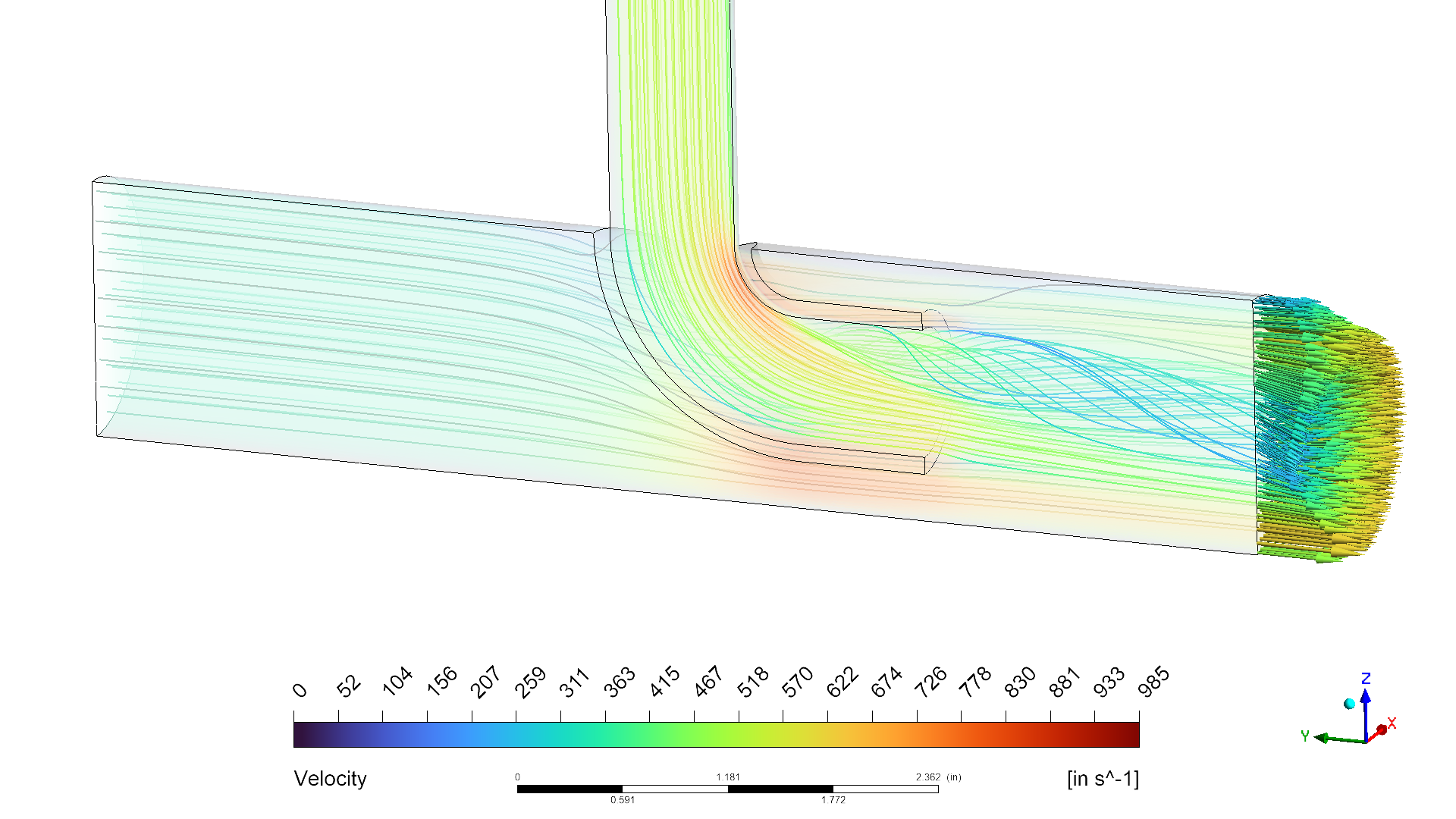

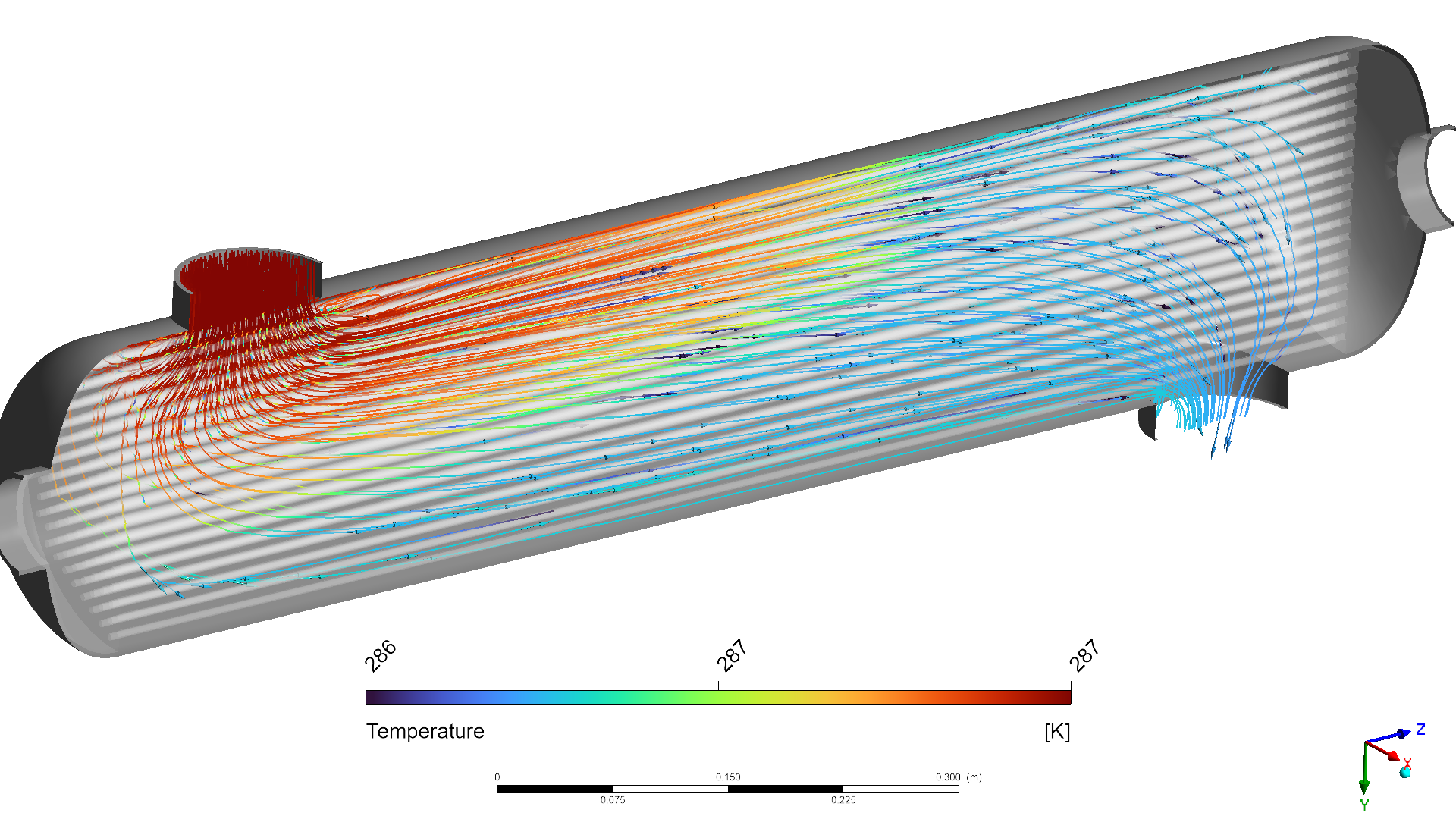

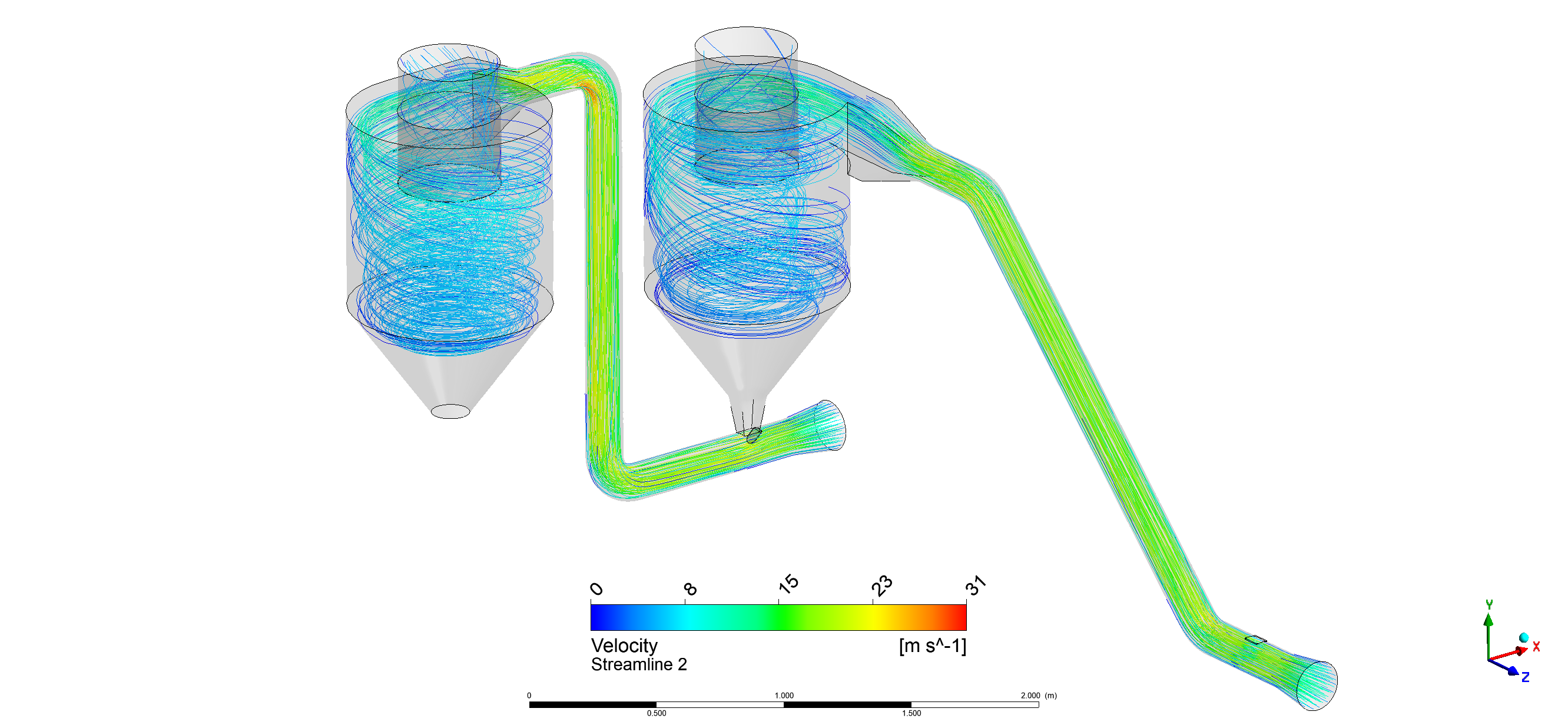

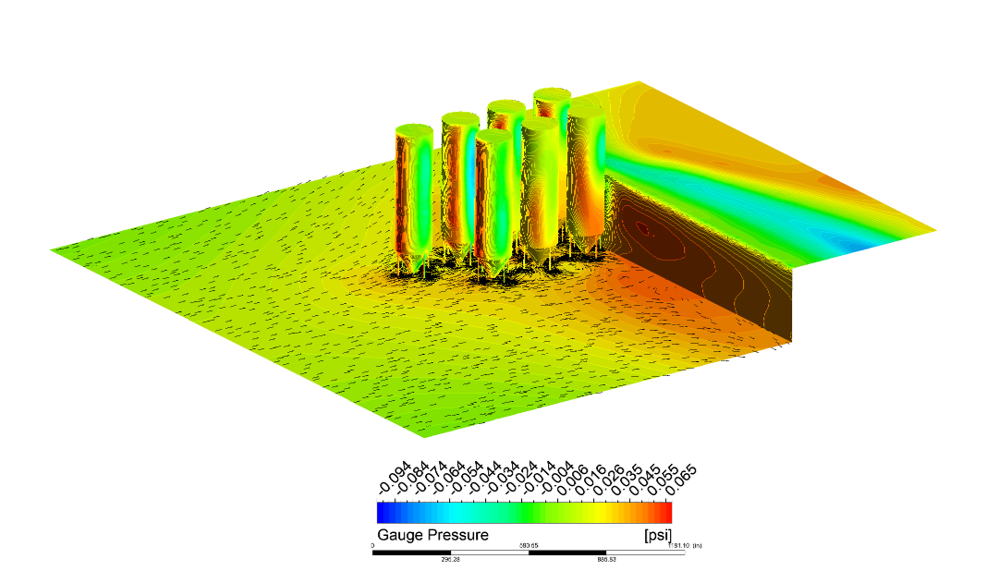

Fluid flow shapes performance – from energy systems to HVAC, from automotive underbodies to industrial reactors. At Fabexco, we use advanced CFD simulation to solve real-world flow problems across a broad range of industrial sectors. Whether optimizing airflow in a heat exchanger, tracking particle transport in a filter, or predicting erosion in a slurry line, our CFD solutions deliver insight that drives smarter design, greater efficiency, and higher reliability.

We bring engineering rigor and simulation expertise to support everything from early-stage design decisions to final system validation – helping you reduce energy use, improve durability, and enhance performance.

Capabilities

- Multiphysics Flow Analysis:

- Compressible and Incompressible Flows: Simulating low-speed and high-speed flows for applications like radiators, HVAC ducts, furnaces, filtration systems, chemical processes, particle transportation systems, industrial machinery, and more

- Hydrodynamics: Modeling hull interactions, propeller designs, and flow around submerged structures for maritime or coastal engineering applications

- Free-Surface/Volume of Fluid Problems: Analysis of liquid-gas interfaces, such as sloshing in tanks, wave interactions, and liquid spill simulations

- Coupled Thermal and Evaporation Modeling:

- Simulating heat transfer, phase changes, and evaporation in applications like heat exchangers, drying beds, refrigeration systems, and industrial drying processes

- Accurate prediction of temperature gradients in manufacturing equipment and processes

- Porous Media Simulation:

- Modeling fluid flow through porous materials, such as filtration systems, packed beds, and geotechnical materials

- Applications include optimizing air permeability in HVAC systems, optimizing filtration system design, and assessing water seepage in civil engineering structures.

- Discrete Particle Analysis (DPM):

- Simulating the behavior of particles, droplets, and sprays in applications like material transportation systems, pharmaceutical processes, and filtration equipment.

- Erosion and Wear Prediction:

- Evaluating machinery wear caused by particulate-laden flows, such as sand suspensions, slurry, and shale oil, to quantify or improve durability.

- Acoustic Propagation and Attenuation:

- Simulating noise generation and propagation in industrial systems, such as axial fans, compressors, HVAC units, and exhaust ducts, with acoustic optimization and attenuation solutions.

- Advanced Optimization and Coupled Physics:

- Integrated analysis involving fluid-thermal-structural interactions to address aero/hydroelasticity, thermal stresses, and flow-induced vibrations.

- Optimization of system components for maximum efficiency and minimal energy consumption using advanced techniques such as parametric or adjoint optimization.

Applications

Our CFD solutions are applied across a diverse range of industries:

- Industrial Machinery: Analyzing flow in pumps, compressors, turbines, ductwork, reactors, distillation columns, and heat exchangers

- HVAC Systems: Optimizing airflow distribution, temperature control, and energy efficiency in buildings and industrial facilities

- Construction: Evaluating wind loads, natural ventilation, and pollutant/particulate dispersion in urban environments

- Automotive: Improving aerodynamics, noise, and thermal management efficiency

- Maritime & Offshore: Enhancing vessel hydrodynamics, reducing drag, improving propeller or jet pump efficiency, and analyzing wave interactions

Typical deliverables include:

- Detailed CFD simulation results, including visualization and tabulated databases of flow velocity, pressure, and temperature distributions

- Performance metrics such as drag coefficients, heat transfer rates, and acoustic profiles

- Erosion and wear prediction maps for critical machinery components

- Optimized designs for enhanced system performance and reduced energy consumption

- Comprehensive documentation, including visualizations, sensitivity studies, and trade-off analyses, tailored to project requirements

Whether you’re improving the airflow in a data center, optimizing a pump system for efficiency, or reducing noise in a ventilation unit – Fabexco’s CFD capabilities help you make informed decisions with confidence and speed.

Get In Touch

Let's Talk About What's Next

We'd love to hear about your project. Whether you're exploring options or ready to move forward, we're here to help. If needed, we're happy to start with an NDA to ensure a productive, confidential conversation.

Reach out and let's see how we can work together.